-

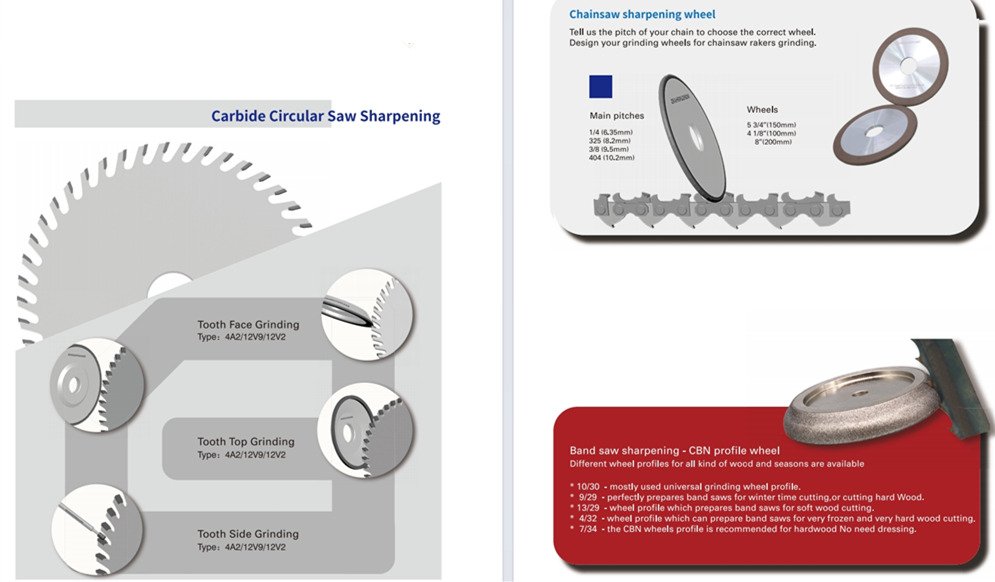

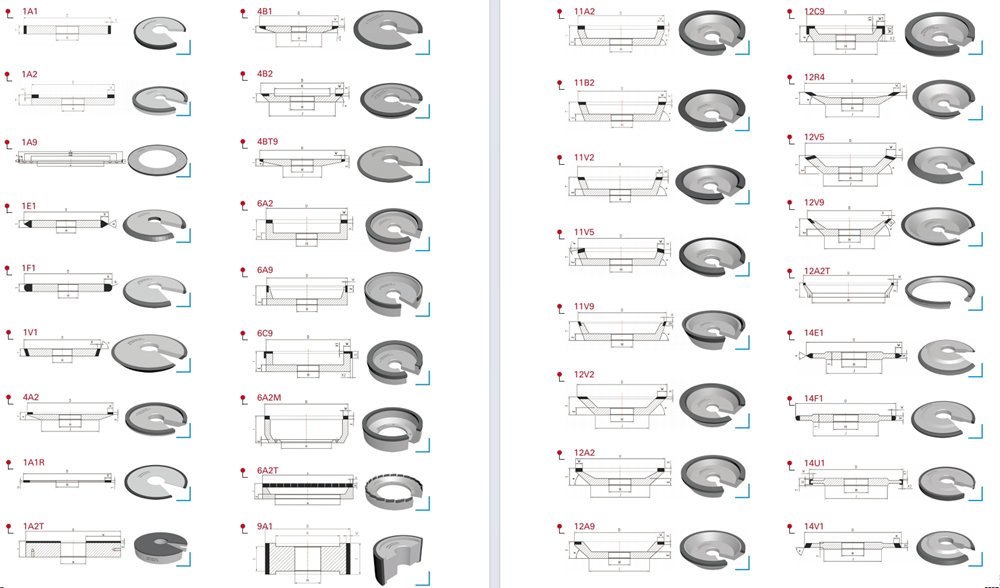

Resin bond Grinding WheelsGET YOUR SOLUTIONSizes: (5mm) - 36 inches (914mm)Grit sizes: #40 - #3000Model: 1A1R, 1A1, 3A1, 1V1, 4A2, 4BT9, 6A2, 11V9, 12A2, 14F, etc

Resin bond Grinding WheelsGET YOUR SOLUTIONSizes: (5mm) - 36 inches (914mm)Grit sizes: #40 - #3000Model: 1A1R, 1A1, 3A1, 1V1, 4A2, 4BT9, 6A2, 11V9, 12A2, 14F, etc -

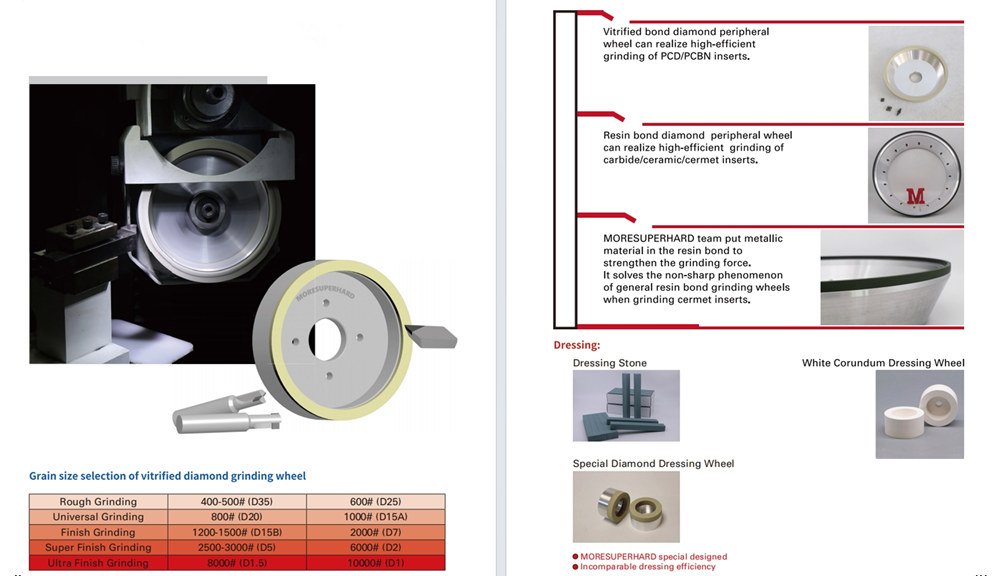

Vitrified Diamond CBN WheelsGET YOUR SOLUTIONDiameter: 8-750mm. Thickness: 1-300mm. Grit: 60/70-W1.5Type: 6A2, 1A1, 1A9, 2A2T, 6A9, 11A2, 3A1, 14A1, etcMost commonly employed in the grinding of PCD and PCBN tools

Vitrified Diamond CBN WheelsGET YOUR SOLUTIONDiameter: 8-750mm. Thickness: 1-300mm. Grit: 60/70-W1.5Type: 6A2, 1A1, 1A9, 2A2T, 6A9, 11A2, 3A1, 14A1, etcMost commonly employed in the grinding of PCD and PCBN tools -

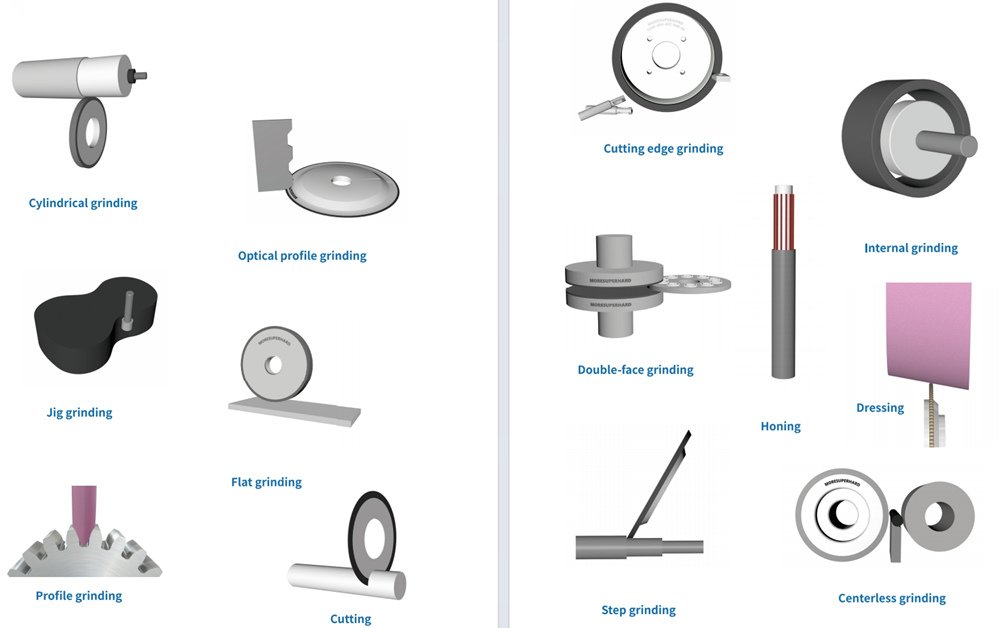

Electroplated Grinding WheelsGET YOUR SOLUTIONPlated grinding wheels for precision grinding, slot grinding, contouring, scoring, facing and internal or external grindingGrain size: Rough grinding 80#-100#, Semi-finish grinding 120#-180#, Finish grinding 180#-W40No Need Dressing

Electroplated Grinding WheelsGET YOUR SOLUTIONPlated grinding wheels for precision grinding, slot grinding, contouring, scoring, facing and internal or external grindingGrain size: Rough grinding 80#-100#, Semi-finish grinding 120#-180#, Finish grinding 180#-W40No Need Dressing -

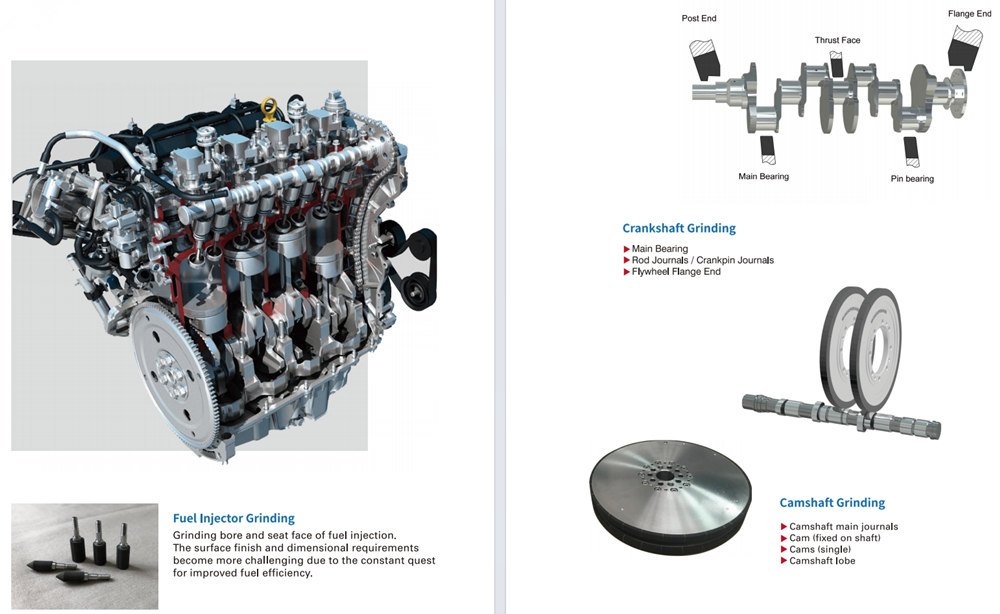

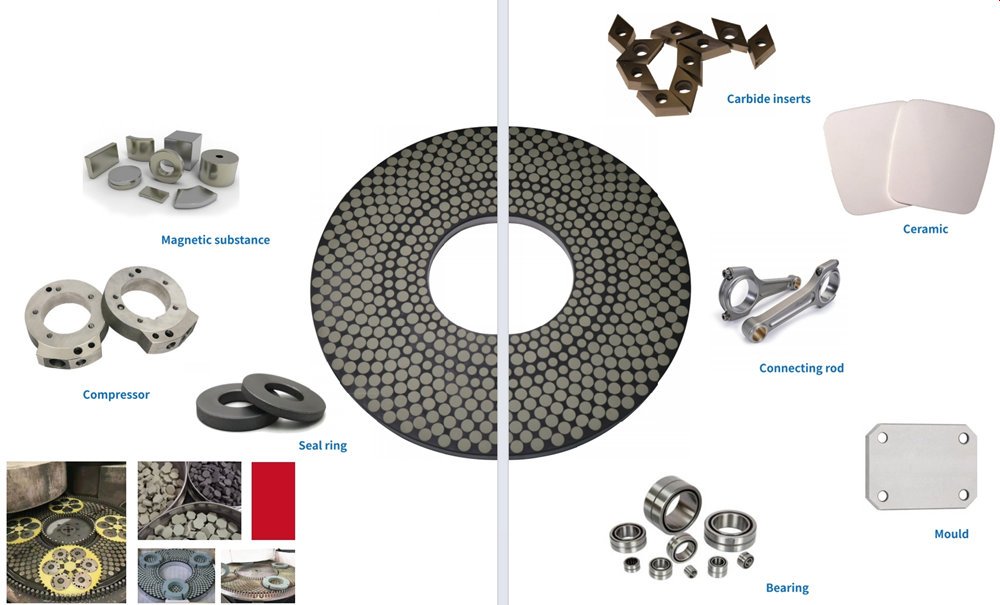

Metal bond Grinding WheelsGET YOUR SOLUTIONApplications: Optical Glass, Tungsten Carbide, Steel (Stainless, and heat resistant), Ceramic, Quartz, Titanium Alloy, Automotive Parts Manufacturing. Air Condition Parts Manufacturing.Metal bond wheels can be utilized in wet or dry grinding applicationsModels: 1A1, 1V1, 2A2T (Blanchard Style), 6A2 (Double Disc), 1E1, 4BT9

Metal bond Grinding WheelsGET YOUR SOLUTIONApplications: Optical Glass, Tungsten Carbide, Steel (Stainless, and heat resistant), Ceramic, Quartz, Titanium Alloy, Automotive Parts Manufacturing. Air Condition Parts Manufacturing.Metal bond wheels can be utilized in wet or dry grinding applicationsModels: 1A1, 1V1, 2A2T (Blanchard Style), 6A2 (Double Disc), 1E1, 4BT9 -

Diamond Cylindrical Wheel for Thermal Spray CoatingGET YOUR SOLUTIONModel: 1A1, 3A1. Diameters: 1 inch - 36 inches (914mm)For grinding and finishing of thermal spray coatingsFinishing of HVOF thermal spray coating by CBN grinding wheels

Diamond Cylindrical Wheel for Thermal Spray CoatingGET YOUR SOLUTIONModel: 1A1, 3A1. Diameters: 1 inch - 36 inches (914mm)For grinding and finishing of thermal spray coatingsFinishing of HVOF thermal spray coating by CBN grinding wheels -

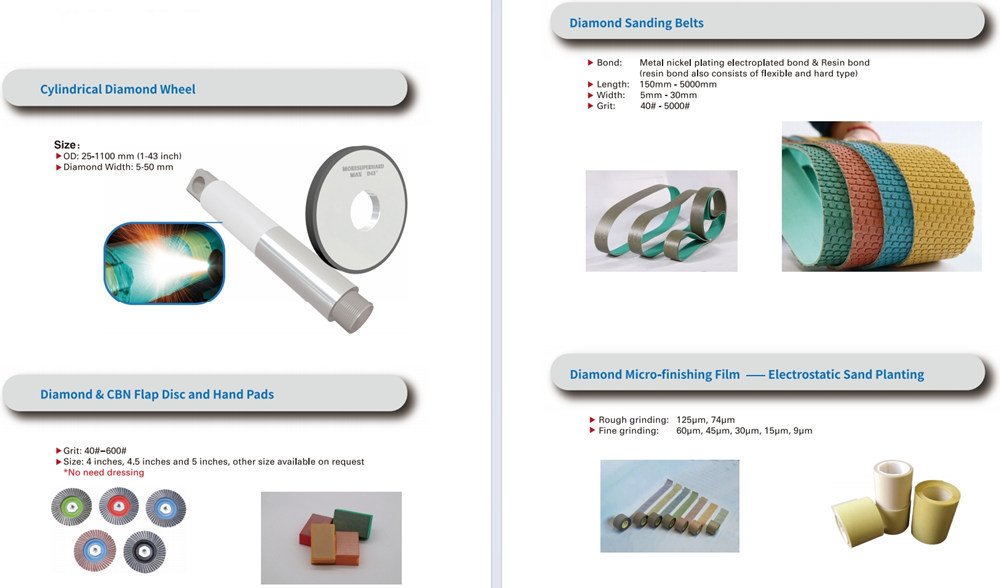

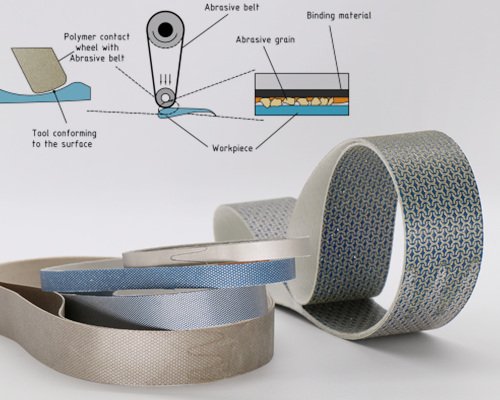

Diamond Sanding Belts for HVOF PolishingGET YOUR SOLUTIONLength: 150mm – 5000mmWidth: 5mm – 350mmGrit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

Diamond Sanding Belts for HVOF PolishingGET YOUR SOLUTIONLength: 150mm – 5000mmWidth: 5mm – 350mmGrit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000 -

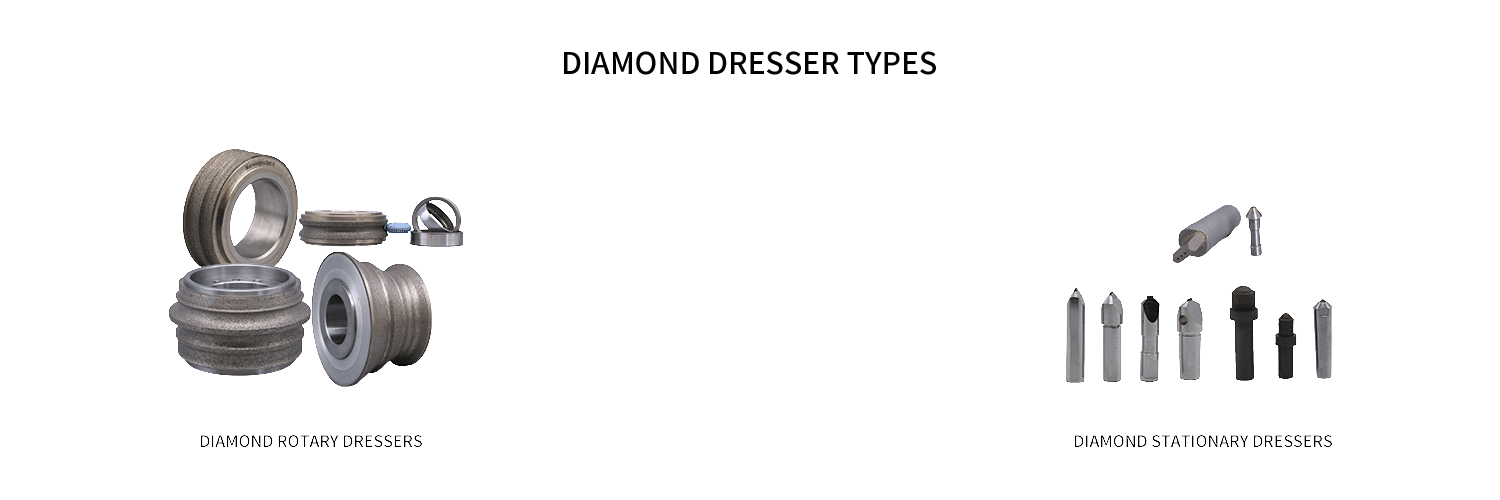

Diamond Rotary DresserGET YOUR SOLUTIONDresser type: reverse plated, sintered, CVD disc dresserThe working principle is that conventional grinding wheels or CBN grinding wheels are forming dressed by the diamond roller dresser installed on the grinding machine

Diamond Rotary DresserGET YOUR SOLUTIONDresser type: reverse plated, sintered, CVD disc dresserThe working principle is that conventional grinding wheels or CBN grinding wheels are forming dressed by the diamond roller dresser installed on the grinding machine -

Diamond Cut Off Wheels, CBN BladesGET YOUR SOLUTIONBond: Resin bond, Metal bond, Electroplated bondTypes: 1A1R, 1A1Diameter : 5″ (125mm) -16″ (400mm). Thickness : 0.3mm – 2.8mm

Diamond Cut Off Wheels, CBN BladesGET YOUR SOLUTIONBond: Resin bond, Metal bond, Electroplated bondTypes: 1A1R, 1A1Diameter : 5″ (125mm) -16″ (400mm). Thickness : 0.3mm – 2.8mm -

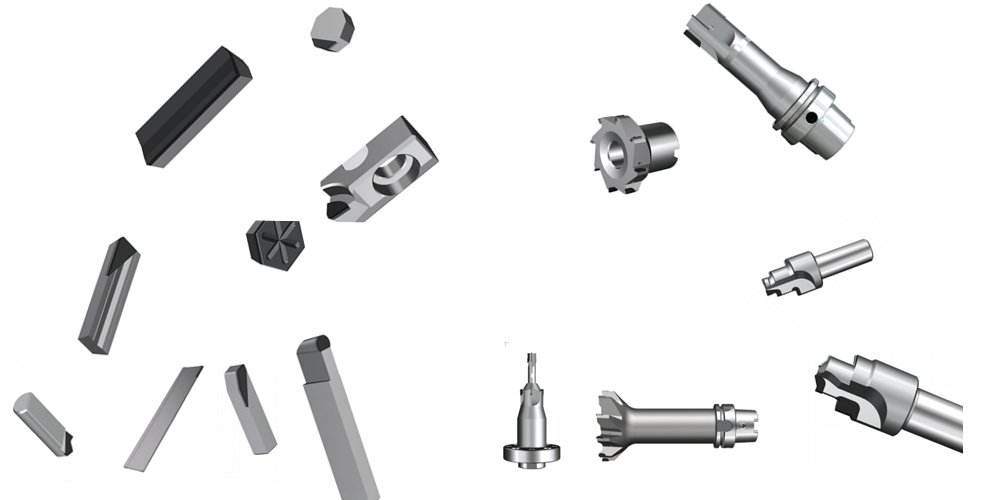

Vacuum Brazed Diamond Tools for Cast Iron in Foundry IndustryGET YOUR SOLUTIONMoresuperhard Vaccum Brazed Diamond ToolsCutting , grinding foundry, metal working, composites, automotive sector, ship building , stone , ceramic, plastic processing ,etc

Vacuum Brazed Diamond Tools for Cast Iron in Foundry IndustryGET YOUR SOLUTIONMoresuperhard Vaccum Brazed Diamond ToolsCutting , grinding foundry, metal working, composites, automotive sector, ship building , stone , ceramic, plastic processing ,etc -

Diamond Honing Tools, Honing SticksGET YOUR SOLUTIONProvides precision bore honing finishing solutionHoning Machine: Sunnen, Nagel, Gehring, Nissin, Engis, Fuji, Mas and other honing machines.Fine grinding engine pump body, hydraulic cylinder bore, hydraulic pump inner bore, cylinder block, valve,oil cylinder nozzle, the inner surface of the spline bore and cylinder hole

Diamond Honing Tools, Honing SticksGET YOUR SOLUTIONProvides precision bore honing finishing solutionHoning Machine: Sunnen, Nagel, Gehring, Nissin, Engis, Fuji, Mas and other honing machines.Fine grinding engine pump body, hydraulic cylinder bore, hydraulic pump inner bore, cylinder block, valve,oil cylinder nozzle, the inner surface of the spline bore and cylinder hole -

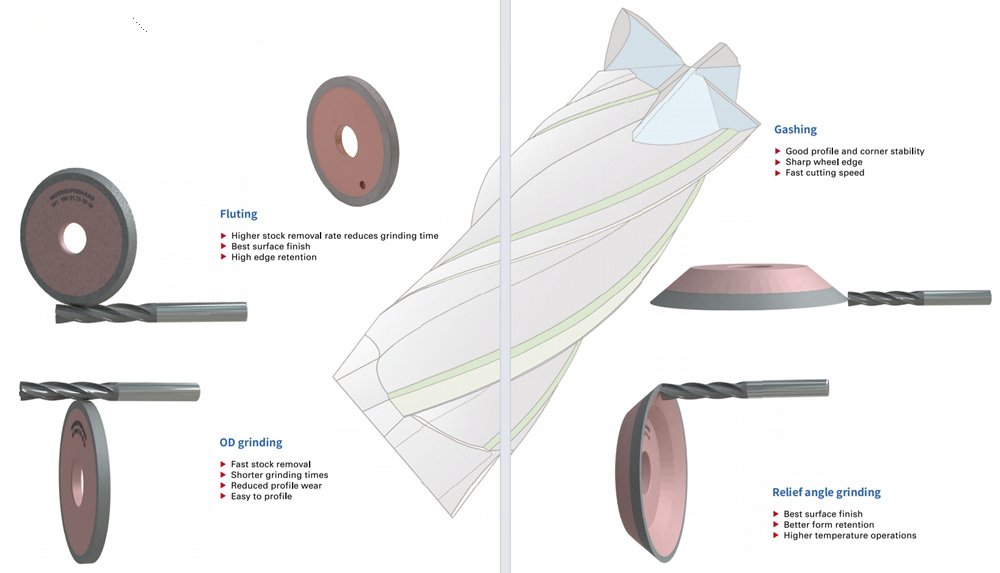

Hybrid Grinding Wheels- Fluting/ GashingGET YOUR SOLUTIONModel: 1A1, 1V1, 14A1, 11V9Application: fluting ,gashing end mill, drill, carbide cutter on CNC Tool and Cutter Grinders.Applicable CNC Grinder: Anca, Makino, Rollomatic, Star, Walter, etc

Hybrid Grinding Wheels- Fluting/ GashingGET YOUR SOLUTIONModel: 1A1, 1V1, 14A1, 11V9Application: fluting ,gashing end mill, drill, carbide cutter on CNC Tool and Cutter Grinders.Applicable CNC Grinder: Anca, Makino, Rollomatic, Star, Walter, etc -

Conventional Abrasive Grinding WheelsGET YOUR SOLUTIONModels: Resin wheels/ Epoxy wheels/ Vitrified wheelsDiameter : 30 mm to 915 mmApplications: casting, mold, gear, automotive, bearing, linear guide, compressor, instrumentation, aerospace and other industries

Conventional Abrasive Grinding WheelsGET YOUR SOLUTIONModels: Resin wheels/ Epoxy wheels/ Vitrified wheelsDiameter : 30 mm to 915 mmApplications: casting, mold, gear, automotive, bearing, linear guide, compressor, instrumentation, aerospace and other industries